Deep in the bowels of The Rockefeller University, through a maze of underground hallways and fickle elevators, is a set of unremarkable brown double doors. A doorbell on the wall glows with a tempting light, beckoning you to press it. Doing so summons a mysterious underground creature known as an “engineer,” a term usually whispered in hushed, frightened tones. When this creature opens the doors, you are transported from a gloomy subterranean hallway into a brightly lit engineering playground. 3D printers line the space, emitting a soft, calming hum, and the faint smell of cut acrylic hangs in the air. “Welcome to the PIT,” says the creature, with a slightly evil cackle . . .

Welcome to the PIT

The Gruss Lipper Precision Instrumentation Technologies Resource Center, also known as the PIT, is Rockefeller University’s dedicated space for prototype engineering—a way to test design concepts and device performance. Almost all of a researcher’s prototyping needs can be met at the PIT. While other universities house makerspaces and machine shops, the PIT is unique in that it is entirely staffed by a full-time, multidisciplinary team of professional engineers who work in one physical location, rather than being spread out among different resource centers.

“Getting the opportunity to imagine something and create it was something I’d never been exposed to before,” says Chad Morton, a researcher in Vanessa Ruta’s lab. The Ruta lab, which studies neural circuit physiology and behavior in fruit flies, builds many of their custom experimental setups in the PIT. Morton has been a frequent PIT user for several years.

“Typically, in the research labs I’ve been in, you just used the equipment that was available,” Morton notes. “That created a bound for how you thought about your projects. You can only do so much based on the equipment that was there. But in the Ruta lab, that limitation didn’t exist because of the PIT.”

With access to a full engineering staff and a range of fabrication equipment, including 3D printers and a laser cutter, researchers who use the PIT have more freedom to design their experiments. “The goal, then, is to think creatively about that experimental setup . . . and what it would take to create it,” Morton says. “I remember coming down to the PIT and thinking, ‘This might be impossible,’ and then having the PIT staff say, ‘Oh, this is possible.’”

To gain access to the PIT, researchers must schedule an initial training session that covers the basic prototyping equipment in the shop. Once trained, they are free to design their own setups and use the equipment to fabricate parts. Their labs are charged a monthly rate and given 24/7 access to the PIT makerspace, allowing researchers to work on their own time. Users can also employ the services of the engineers who staff the PIT, known internally as the “PIT crew,” to help in the design process. The PIT crew can assist with anything from drilling a hole in a plate to designing complex instrumentation.

Jacopo Razzauti, a graduate student in Leslie Vosshall’s lab, first came down to the PIT to laser cut parts for the acrylic chambers the lab uses to study mosquitos. “We had so many assembled acrylic chambers when I came to the lab, and one of the Ph.D. students told me, ‘Oh, you can just make your own.’ That’s the first time I found out about the PIT,” explains Razzauti.

Across the floor from Razzauti and his mosquito chambers, scientists in Daniel Kronauer’s lab study ant behavior using their own laser-cut experimental setups. “[The PIT] allows us to do whatever design we want,” says Yohann Chemtob, a postdoctoral researcher in the Kronauer lab. “And each new design allows us to answer new questions.”

If something demands a more advanced engineering solution, users can schedule a free initial consultation with the PIT crew to determine whether a project will be feasible. If it is, the project process begins, with engineers dedicating time to the design and fabrication of the device or custom parts specified in the project scope. The PIT crew charges labs for this work at a rate of $45 per hour—a quarter of the cost of some private engineering firms. Users outside of Rockefeller can also employ the PIT’s services at a higher rate of $100 per hour.

Projects range from quick, one-time-use devices to more permanent setups that can be used for multiple experiments. One such example is the Vosshall lab’s “HOStel” project, which consists of automated laser-cut acrylic gates controlled by motors. It is used to study mosquito behavior without the researcher needing to be in the room. According to Razzauti, the setup is still used to this day.

A PIT of History

In the ancient year of 2015, or 5 BCE (Before Covid Era), the PIT was known as the Precision Fabrication Facility, or PFF. The PFF was a simple makerspace with a few MakerBot 3D printers, some manual machining equipment, and a Roland CNC milling machine. It was run at the time by an engineer named Jim Petrillo. Alipasha Vaziri, a Head of Laboratory (HOL) studying novel ways to image brain tissue samples, found an increasing need for custom instrumentation and parts. Faced with the high costs and long wait times associated with outsourcing engineering work to third-party vendors, Vaziri, along with several other Rockefeller HOLs who now make up the Scientific Advisory Committee, proposed an in-house resource center that could build custom instruments for scientific purposes.

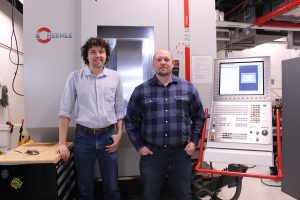

When the need for more advanced parts surpassed the capabilities of the equipment, a five-axis CNC milling machine was purchased from Hermle in 2016. CNC milling is a type of machining that uses programs to mill a piece of material down to a desired shape. The Hermle, as the machine is called, is one of the most advanced CNC machines manufactured today. This behemoth is the size of a small box truck but can carve down a piece of material to 5-micron precision. The machine can be incredibly loud and moves incredibly fast, and when it starts running a program, one could be forgiven for having an initial instinct to run under a table and hide.

Since the Hermle weighs nine metric tons, it needed to be placed on bedrock. Because of this and other space constraints, the PFF moved from level B of the Theobald Smith Building to its current home in the Plaza Building basement. The shop also needed someone to run the Hermle. Peer Strogies was hired as a Scientific Machinist to use the Hermle to make precise parts. With Strogies’ assistance, the Hermle was up and running by January of 2018.

At first, the machine shop and the Hermle made up a new department called the Instrumentation Design Fabrication Facility, or IDFF. In October of 2018, the IDFF and PFF were combined and renamed Precision Instrumentation Technologies, staffed by Petrillo, Strogies, and Dan Gross. The PIT has continued the practice of keeping a full team of engineers on staff and is currently run by Strogies (as the PIT Director) and Instrumentation Engineers Griffin Dennis and me, Nick Belenko.

PIT People: The Staff of the PIT

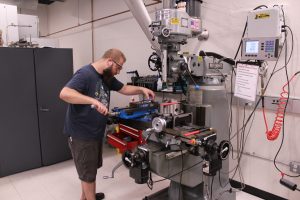

In order to meet the needs of the research community, the PIT contains not only high-end machines, but also staff with the expertise to run them. The most advanced of these machines, and arguably the star of the show, is the Hermle 5-axis CNC milling machine, primarily operated by Peer Strogies. Strogies, a master craftsman by trade, specializes in machining small parts that require great precision and tight tolerances—for example, brain imaging windows for marmosets and macaques, primarily used by the Freiwald lab. Peer also operates manual (non-computer-controlled) machines such as the manual milling machine, lathes, and saws, to name a few.

Each member of the PIT crew, while able to use any machine in the shop, has their own specialty when it comes to engineering and fabrication. Depending on the focus and scope of a project, one or more members of the PIT crew will be involved. “It’s a close collaboration with the people at the PIT . . . and at the end of it, you end up with this experimental setup that allows you to probe all sorts of questions,” explains Morton.

If a project involves 3D-printed parts or other rapid prototyping, Griffin Dennis is the one to talk to. Dennis is a mechanical engineer who can take a rudimentary drawing or concept and transform it into a fully realized 3D part. A self-admitted “3D printing convert,” he’s an expert on the PIT’s various 3D printing technologies, which range from simple Prusa filament printers to the slow but lovable giants that are the ProJet printers. He can create a 3D model and turn it into a physical part in a matter of hours. He also works in the PIT’s machine shop, where, using the saws, mills, and lathe, he can manually create parts with remarkable precision.

If a project involves electronics, data acquisition, sensors, or any other electronic system integration, it becomes my territory. I am an electrical engineer by trade and can condense experimental setups into small packages. I can turn messy jumper wires and breadboard setups into printed circuit boards, or PCBs, allowing seamless functionality between various pieces of equipment.

To Pit or Not To Pit: That Is the Question

Exiting the PIT through the double brown doors can produce a range of emotions: excitement, melancholy, and the urge to see sunlight. But above all is security; users know that at the end of the day, the PIT will be there to assist their research in any way it can.

Having a full shop stocked with tools and prototyping equipment leads researchers to imagine what they could create. From a heated surgery stage for mice to an N95 mask disinfector and even a sperm collection chair for marmosets, the PIT has worked on a huge variety of projects. No problem is too small, either—people can come down with simple jobs such as drilling a hole into a metal plate or soldering wires together.

“I encourage people to explore the PIT,” Morton says. “You never know where inspiration might come from.”

Engineering skills are in increasing demand for many areas of science, but not everyone has the training or knowledge. In that case, why not utilize the PIT? You can receive training for any piece of equipment to develop your own devices, and you can always outsource advanced engineering work to us. With our engineering skills, enthusiasm, and access to high-end prototyping equipment, the PIT crew can make a scientist’s dreams a reality, truly embodying the university’s mission statement: “Science for the benefit of humanity.”

The PIT is located on The Rockefeller University’s campus in the Plaza Building room A4, one floor below the Receiving Department. Visitors are welcome.

All photos by Nick Belenko & Griffin Dennis